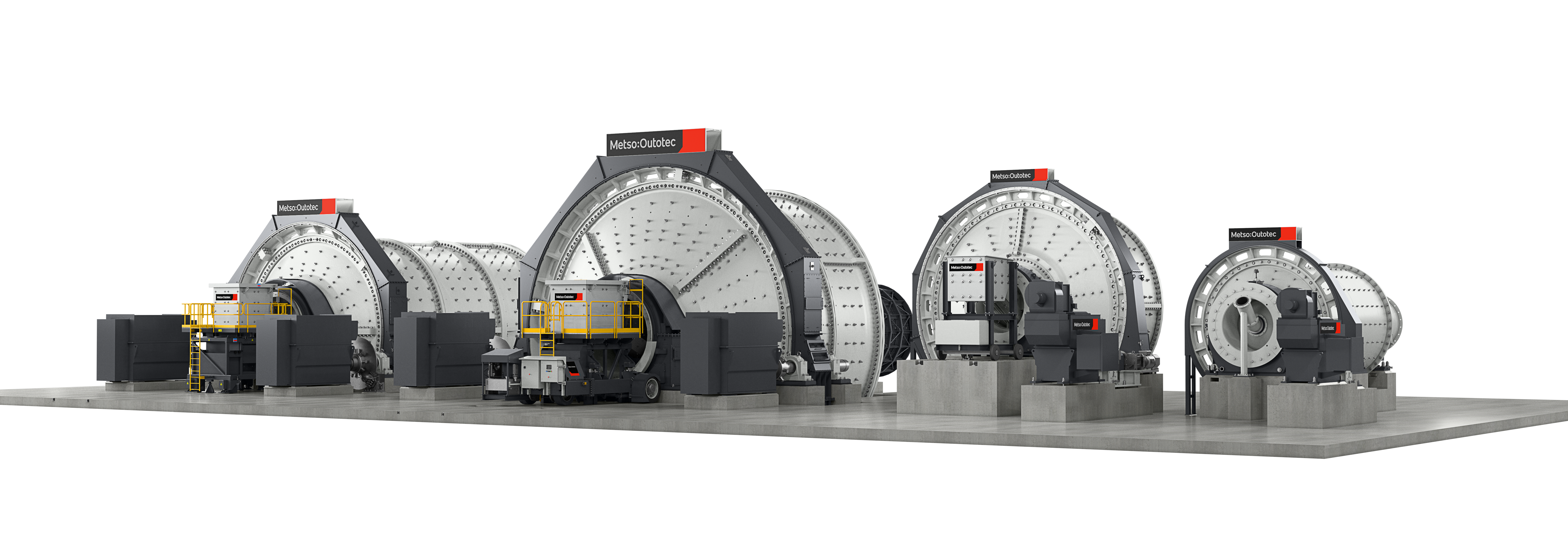

Metso offers a full portfolio of parts, services, and equipment to ensure that you get the best out of your grinding process and reach your production and sustainability goals.

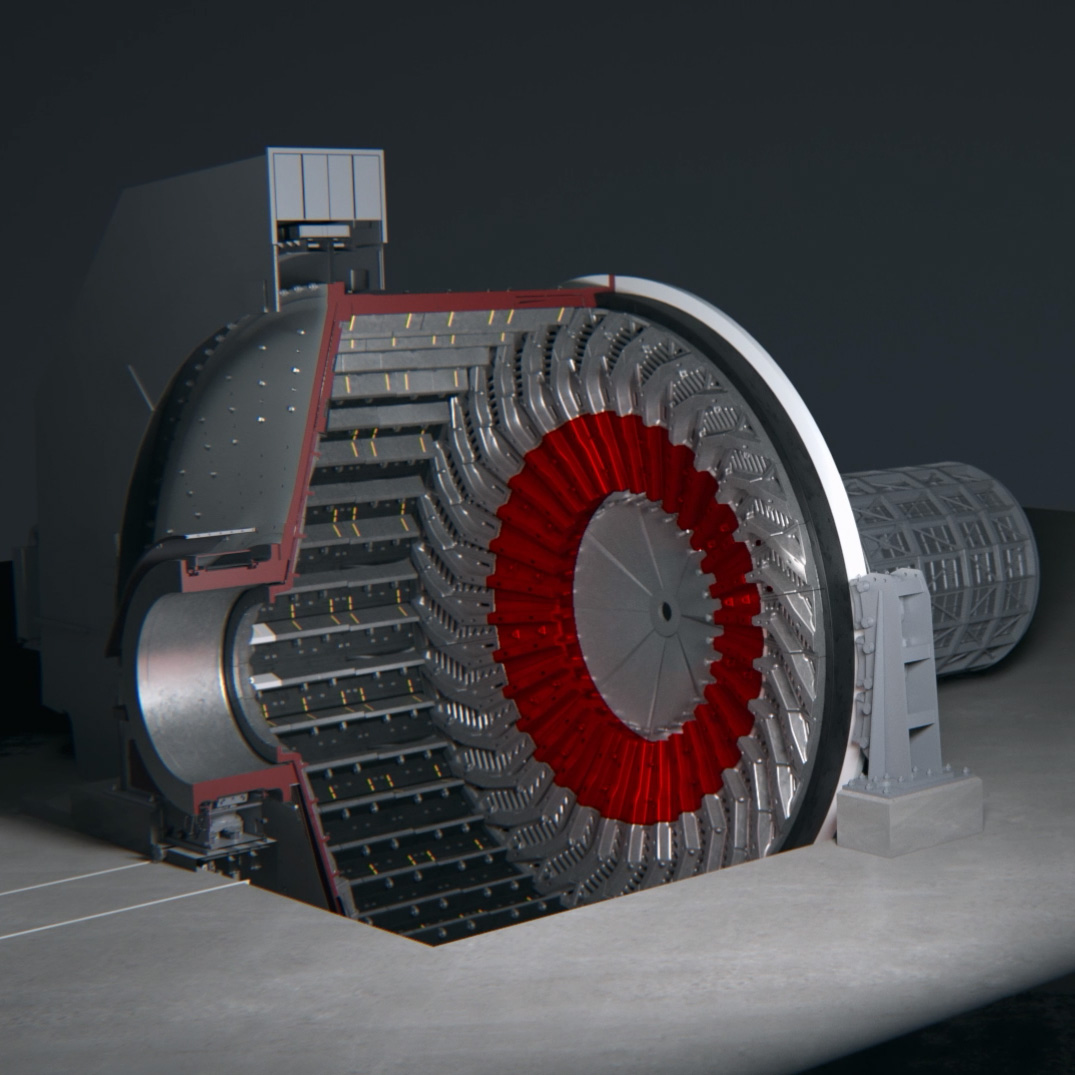

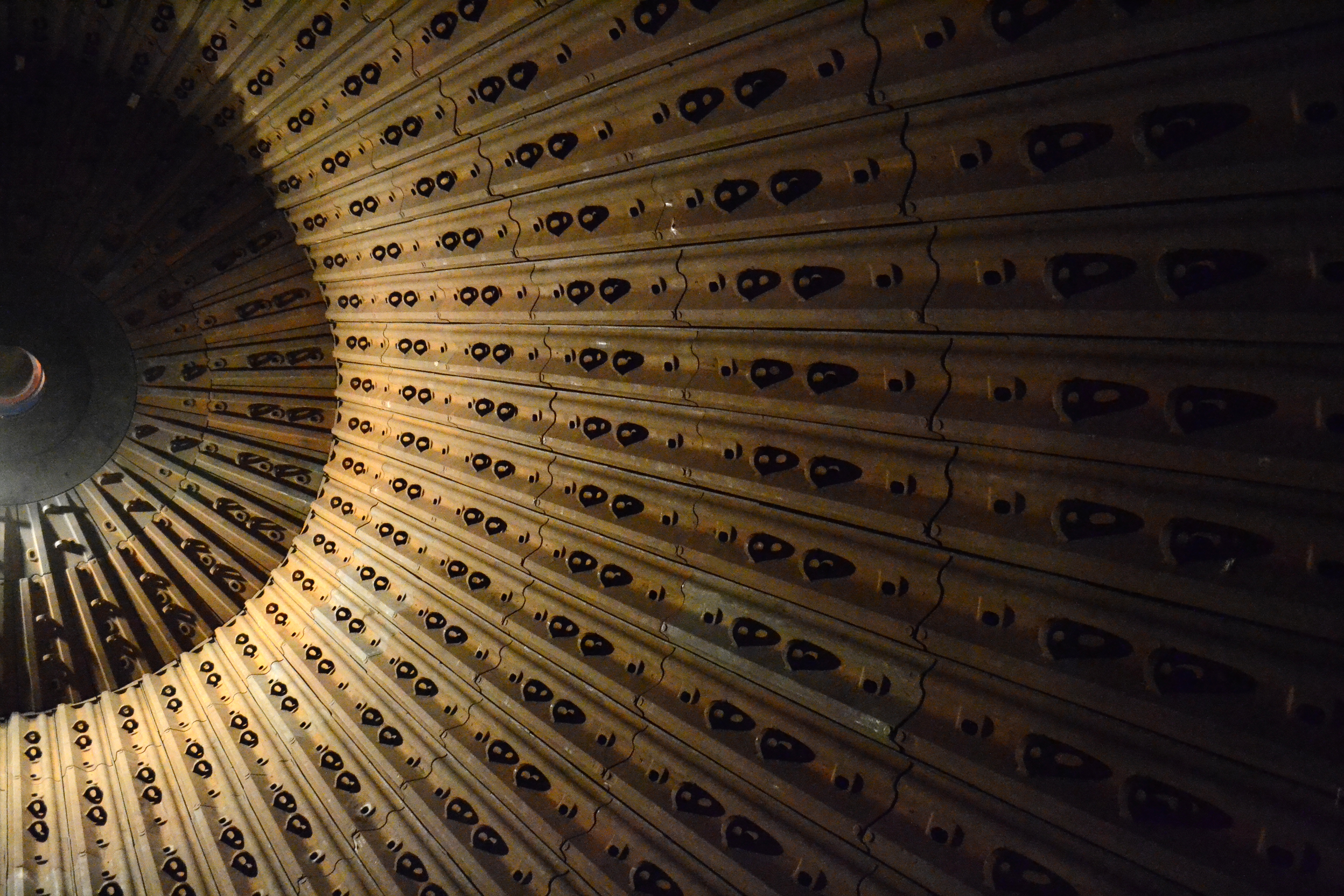

More than a lining

When buying a mill lining from Metso you get more than just a wear part. We always do a pre-study and design the lining based on your conditions and targets. Wear and performance monitoring are regularly done to better understand your grinding process and to optimize the lining accordingly. Technical support is offered, and we arrange product and process training, as well as technical development meetings, for our loyal customers.

Read more on wear monitoring.

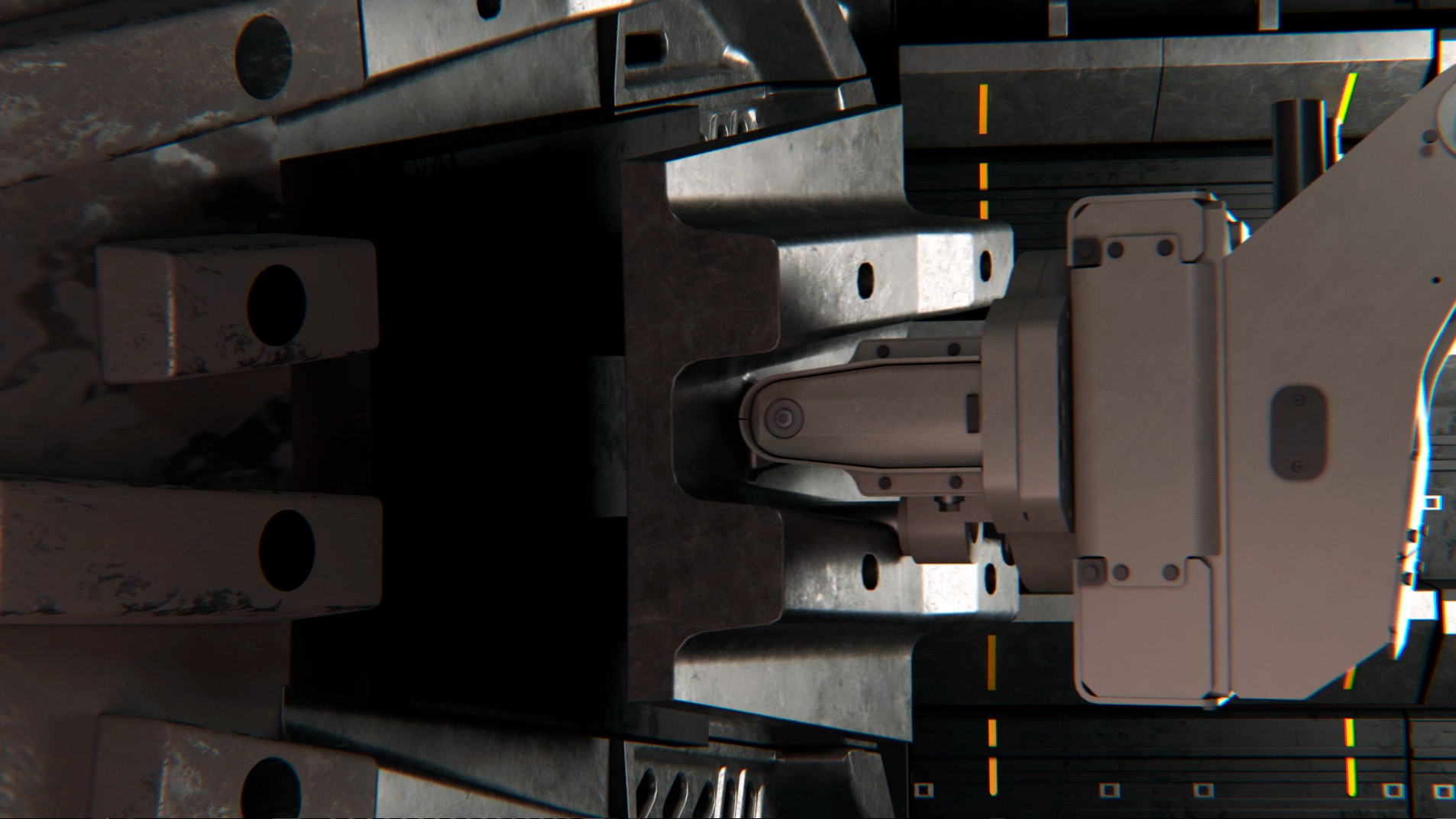

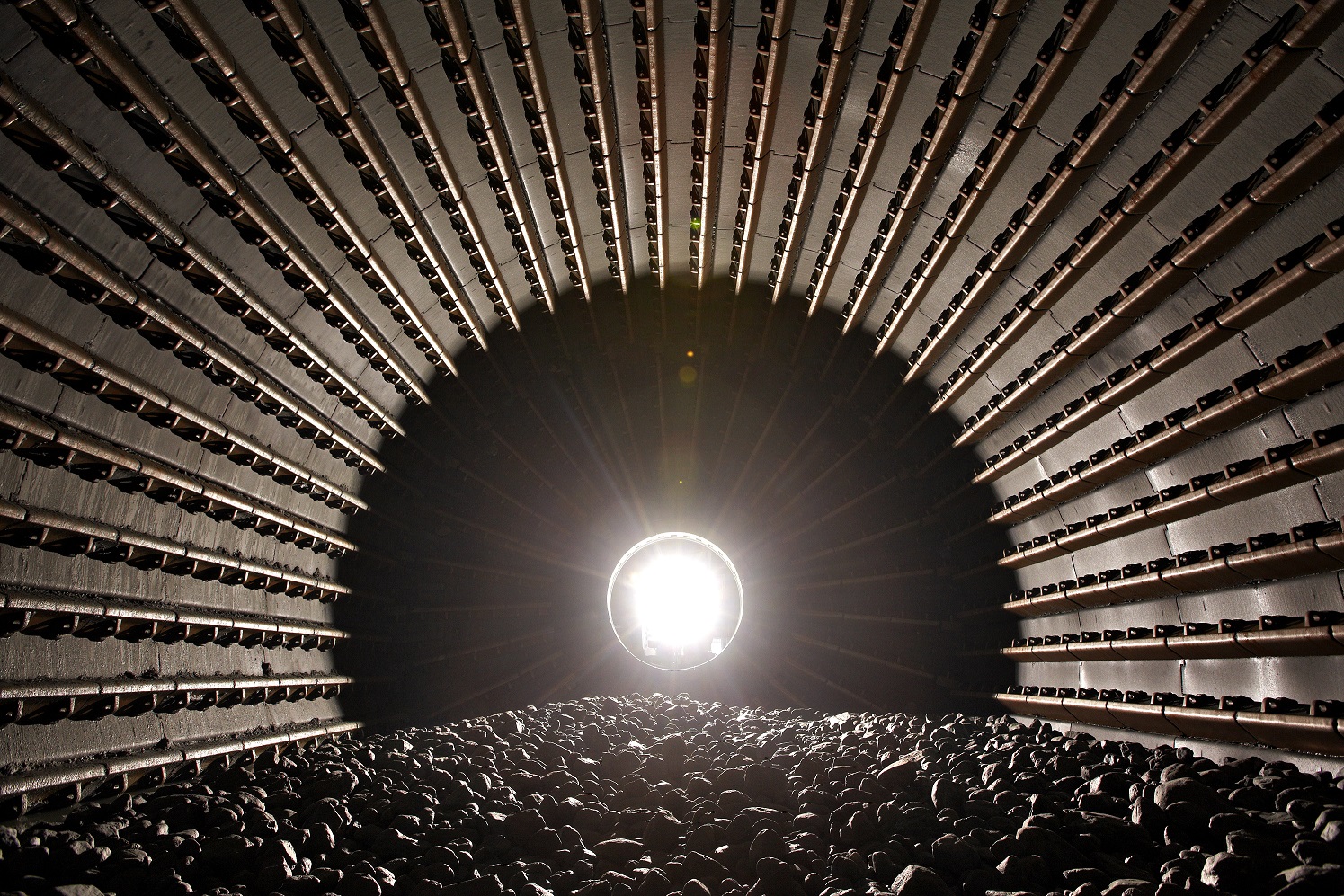

Installation and reline

Our experienced engineers oversee the safe and timely installation of Metso-supplied parts. Our experts adhere to the most stringent safety standards and are highly trained in OEM workmanship, allowing for a high-quality installation. If necessary, Metso can also guarantee the amount of downtime needed to perform wear part changeouts.

Read more on mill reline services and mill reline machines.

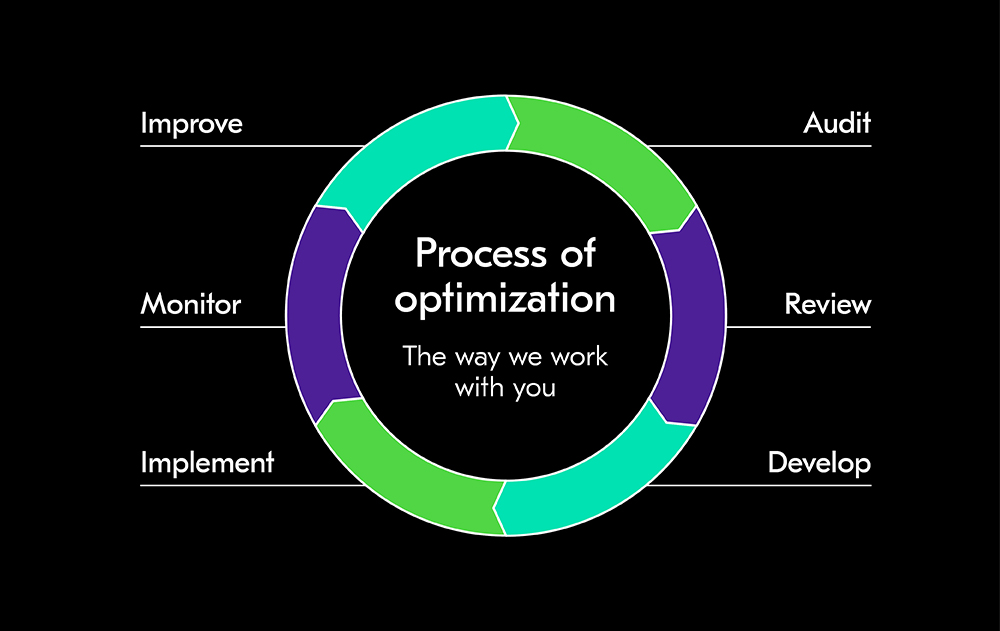

Grinding circuit optimization

Metso process experts help in solving complex operational issues using analytical techniques, laboratory testing, and advanced control systems. Whether you need to optimize a piece of equipment, a circuit, or your entire plant, we have the tools and technology to help you make it happen.

Read more on Process optimization and controls.

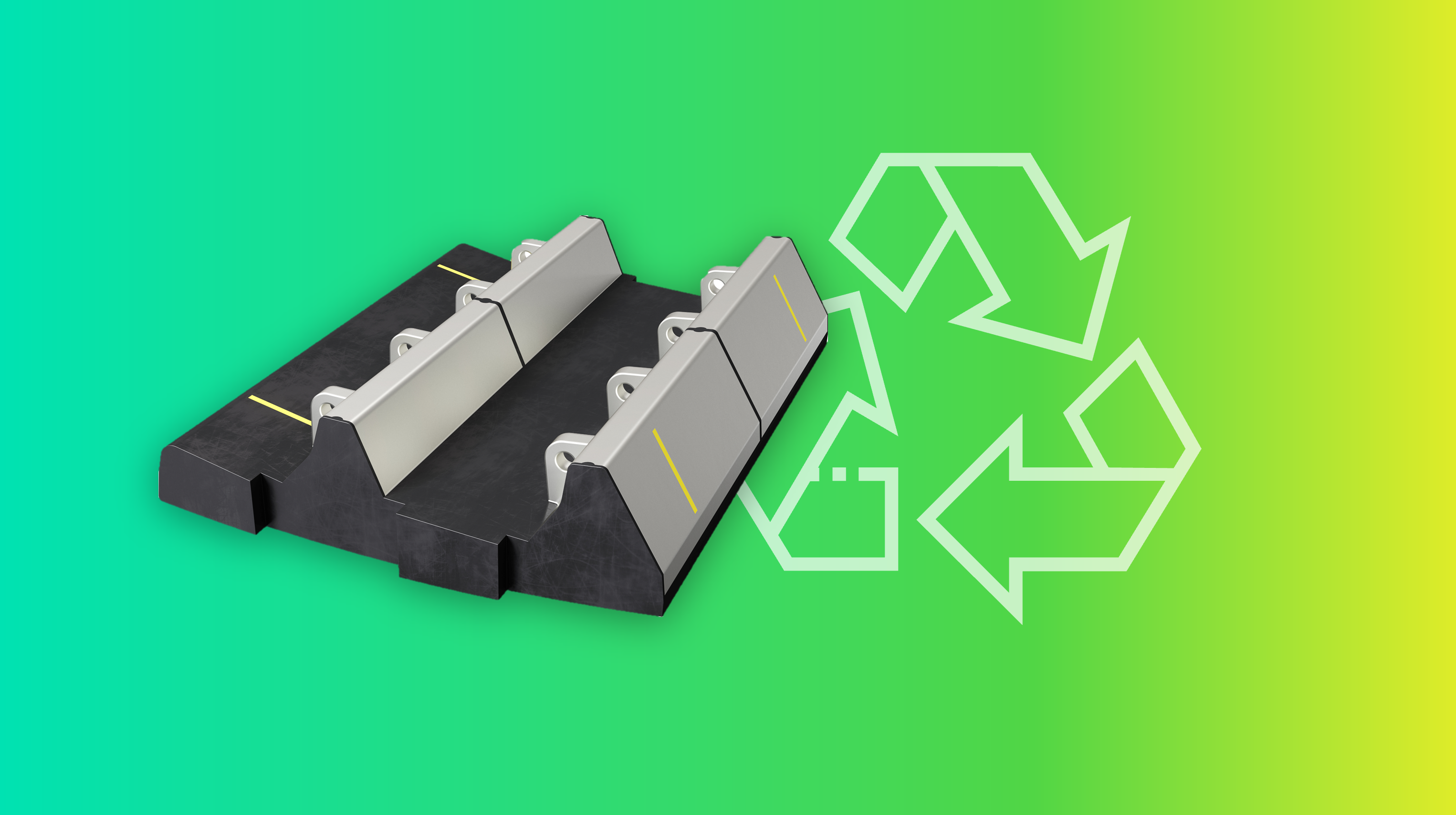

Life Cycle Services

Metso’s pre-packaged solutions are designed to assist you in meeting your business goals, from start-up to shutdown to end-of-life. We can support you on a specific activity or over a larger scope, combining elements from our large portfolio of services with unique commercial models.

Read more on Life Cycle Services.