As part of our mill lining offering, we first launched our recycling service for worn mill liners in Europe and have now introduced this innovative service to South America, and more regions will come. This first-of-its-kind service aims to recycle and create value from used mill liners on an industrial scale. So how can mill liner recycling help you reach your sustainability targets and solve the problem of disposal of worn liners?

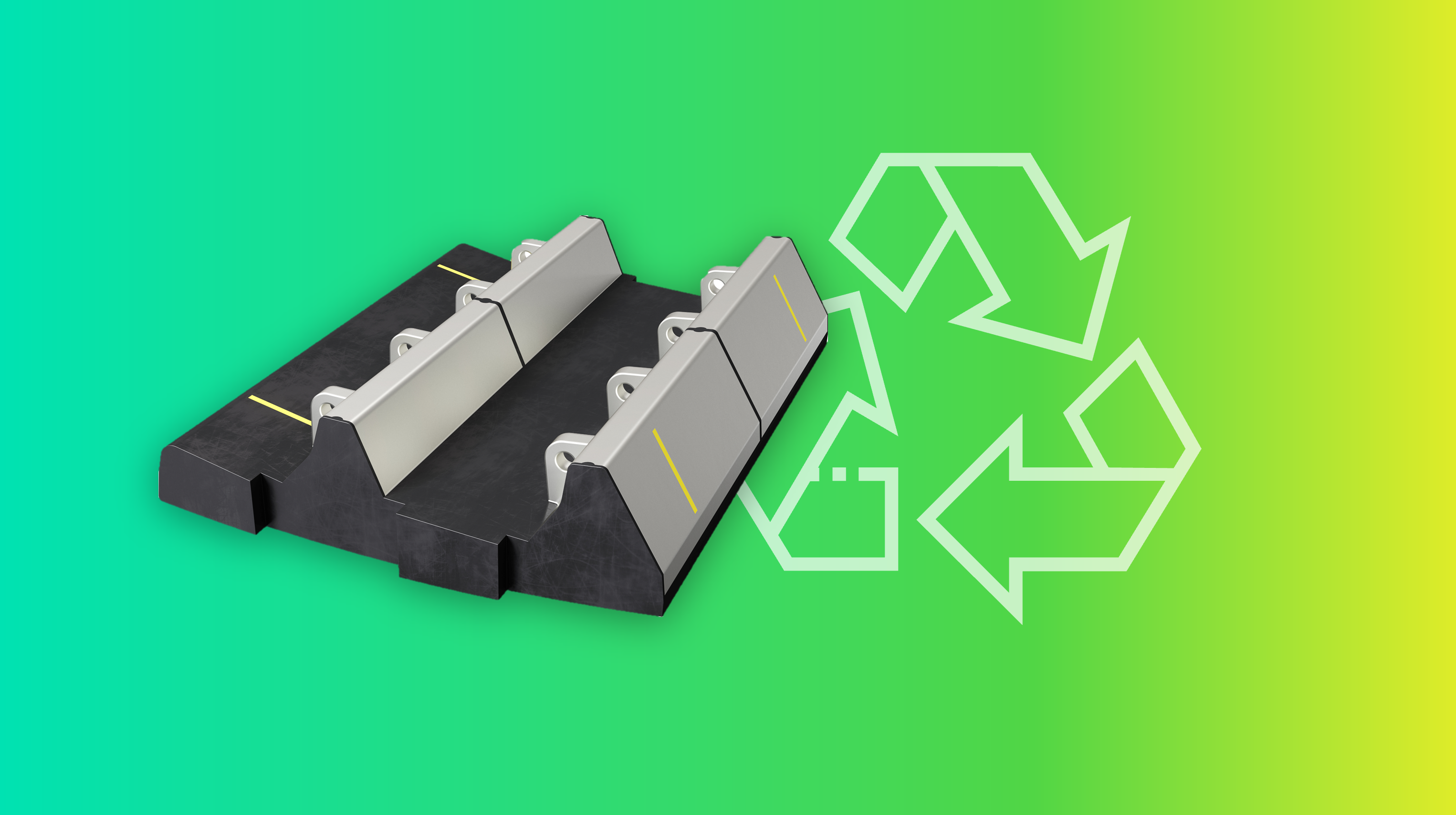

Metso has been studying methods to better recycle rubber and Poly-Met mill liners for several years. The objective was to identify a safe, environmentally friendly, and cost-efficient process to dismantle worn out liners. Lars Furtenbach, Director, Research & Technology Development, Mill Lining, who has been part of the development process since the beginning, and Markus Marttiini, VP, Optimized Mill Lining, describes how you can benefit from recycling of worn-out liners and how it can help you to lower your carbon footprint.

“Metso wants to accelerate the circularity of all wear parts and materials. Metso’s separation line is a crucial step on that path. We are also exploring ways to increase the number of recycled materials in our liners to further close the circularity loop,” Lars Furtenbach explains.