Metso's ball feeding technology utilizes a simple and robust design to continously and efficiently feed the grinding mill. With this in place, the grinding mill can operate at maximum productivity levels compared to those mills without a grinding media feeding system.

Select™ ball feeders are designed for all applications using steel ball grinding media.

Simple and robust

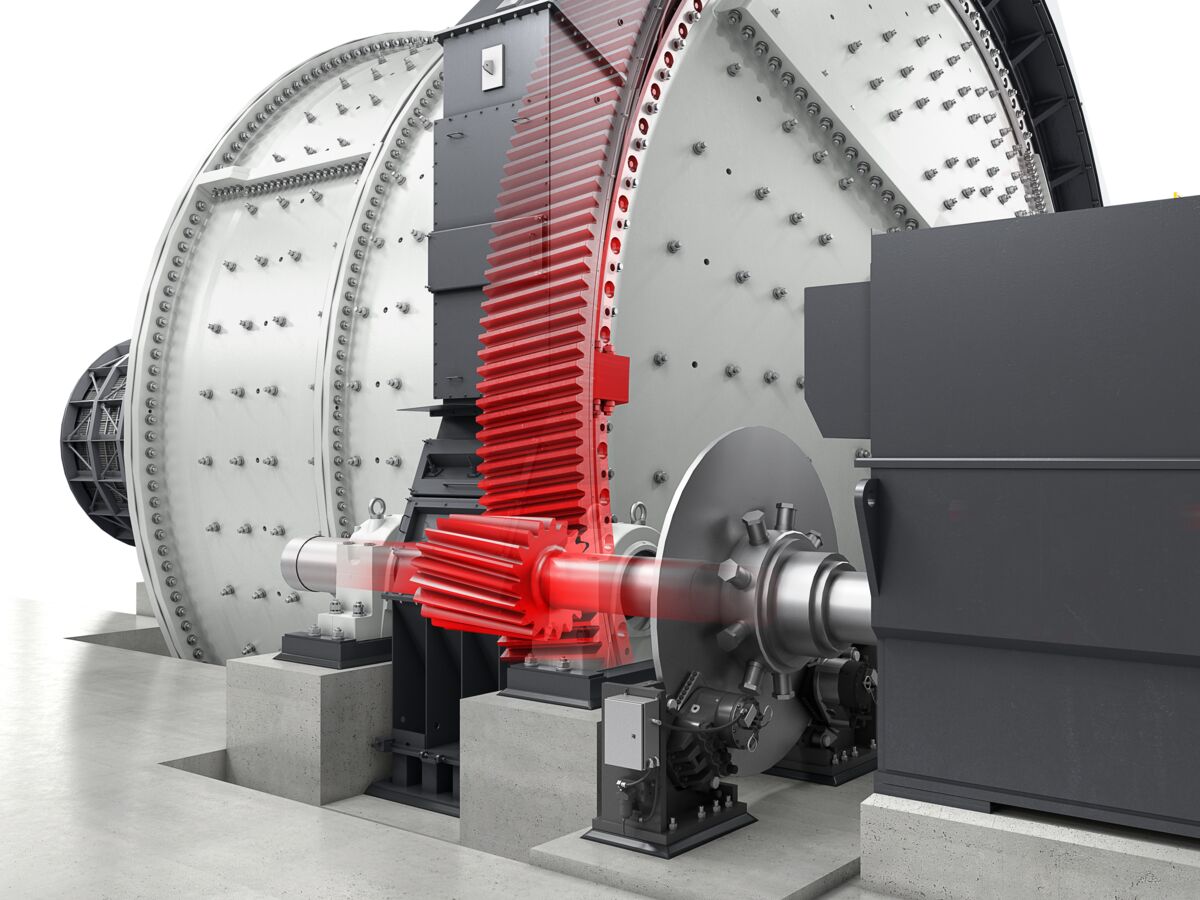

The hopper outlet discharges onto a cleated belt conveyor to feed the grinding media. The mining duty conveyor is the only moving part of the feeder. This consists of a heavy duty cleated belt, high efficiency motorized pulley with an integral helical gearbox and heavy duty idler pullies.

The conveyor is of a standard design, with spare parts that are interchangeable between all Select™ Ball Feeder sizes.

Easy to operate and accurate

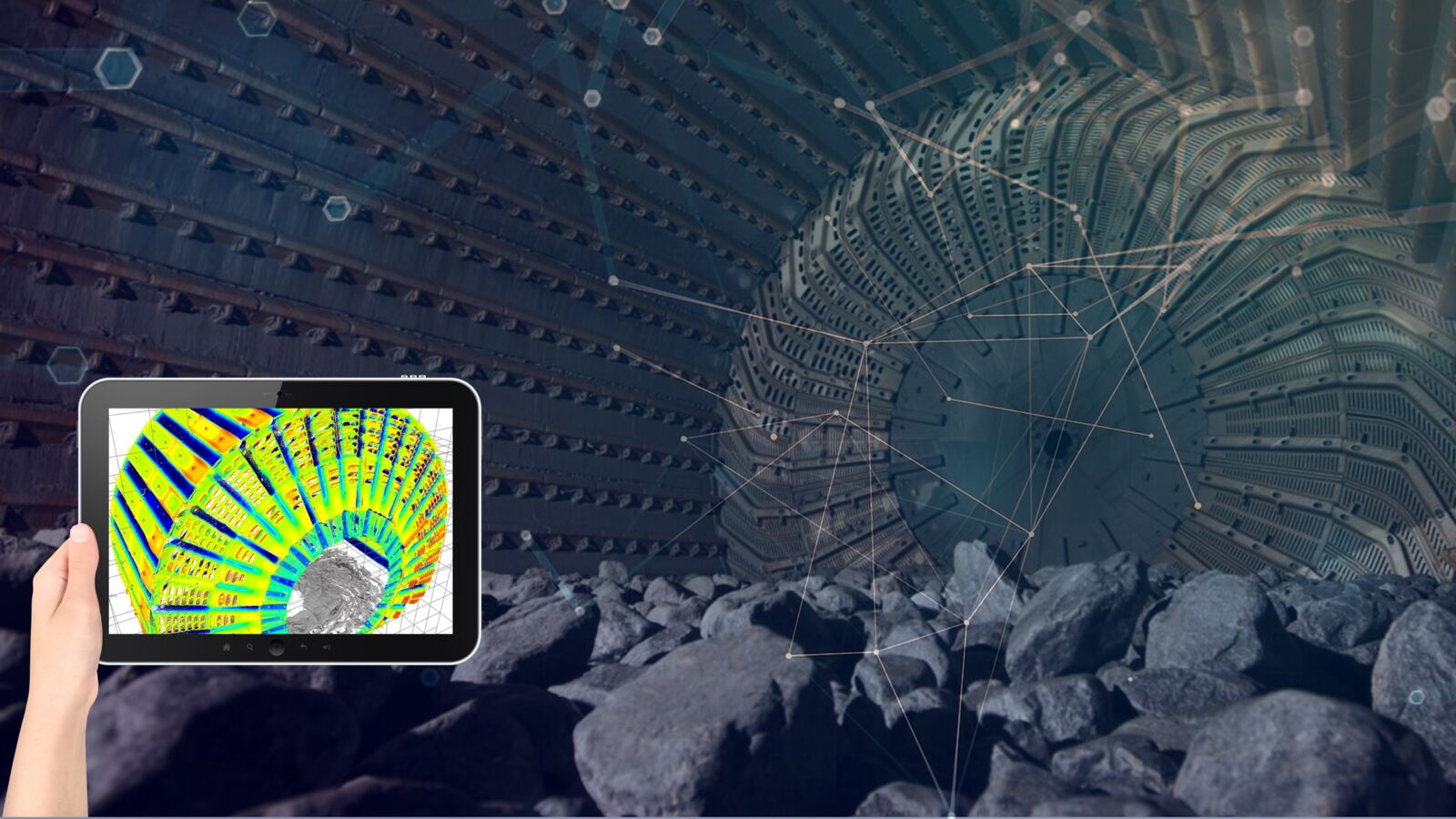

Changes in the mill process parameters require variations to the media feed rate. The Select™ Ball Feeder is easily adjustable and can be changed from the operator control desk.

Feeder design

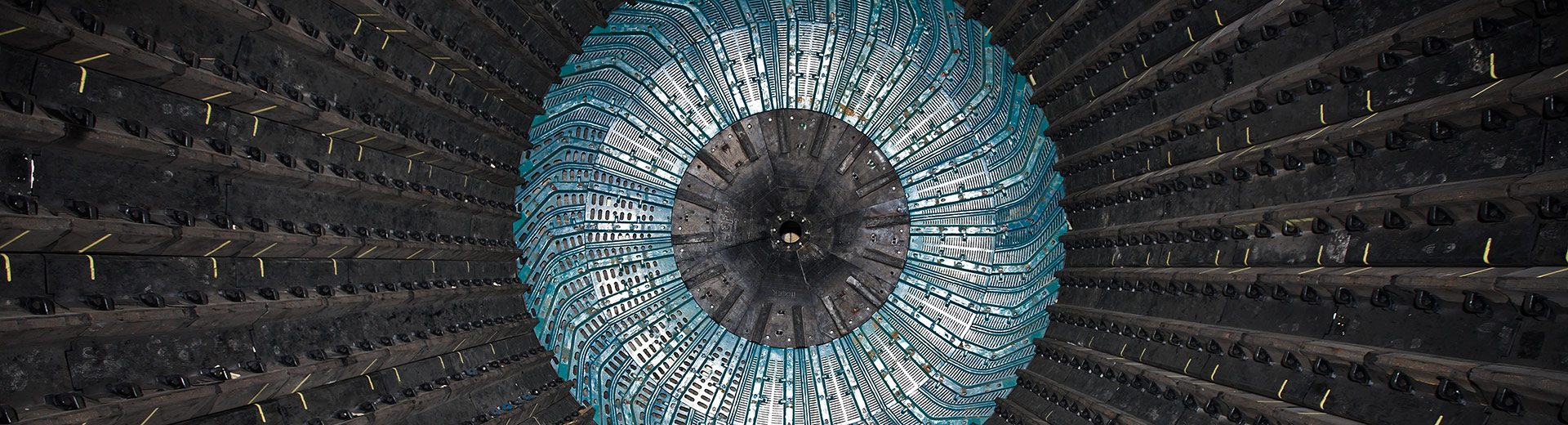

The hopper is a welded steel bin that rests on three load cells. The load cells sit on a welded steel structure that is bolted to the plant floor. The hopper is lined with bolt on Trellex PP steel reinforced rubber lining sheets to reduce wear, vibrations, and noise.

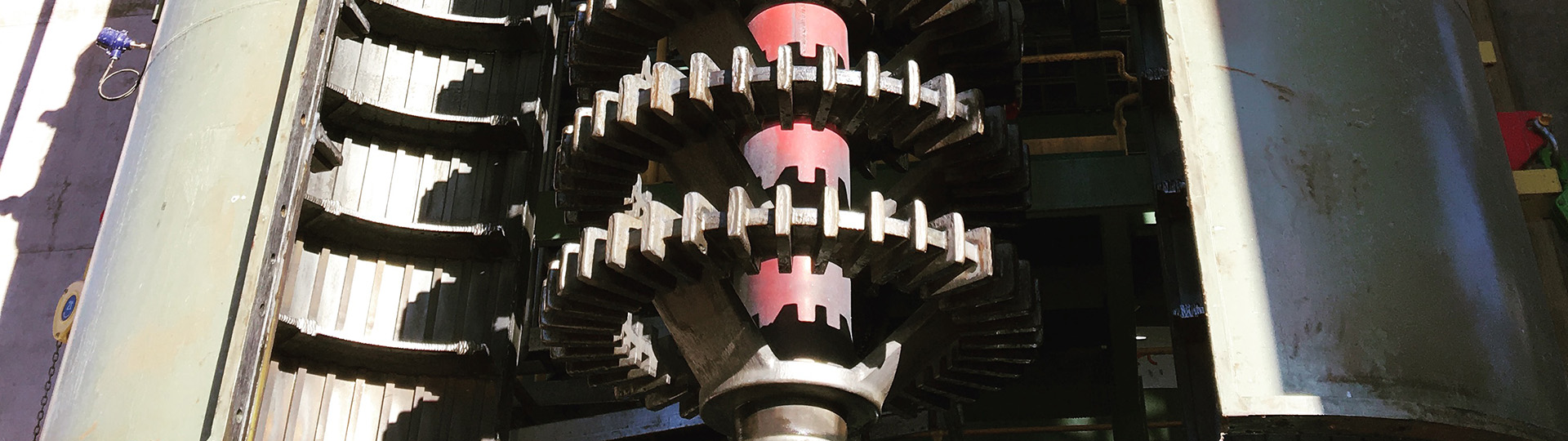

A conveyor is mounted below the hopper and is equipped with a motorized pulley belt conveyor drive, support/return rollers, and a reinforced rubber belt with cleats. The cleats deliver a volume of balls according to the control system set points.

When in Run mode, the motorized pulley belt conveyor drive is started via a user adjusted timer. A rotation sensor detects rotation of the return pully and provides pulses to confirm belt movement. The conveyor stops when a user defined set number of pulses are received.

The Select™ Ball Feeder is provided with a local junction box to connected to the plant PCS/DCS.