Accurate level control for improved metallurgical performance

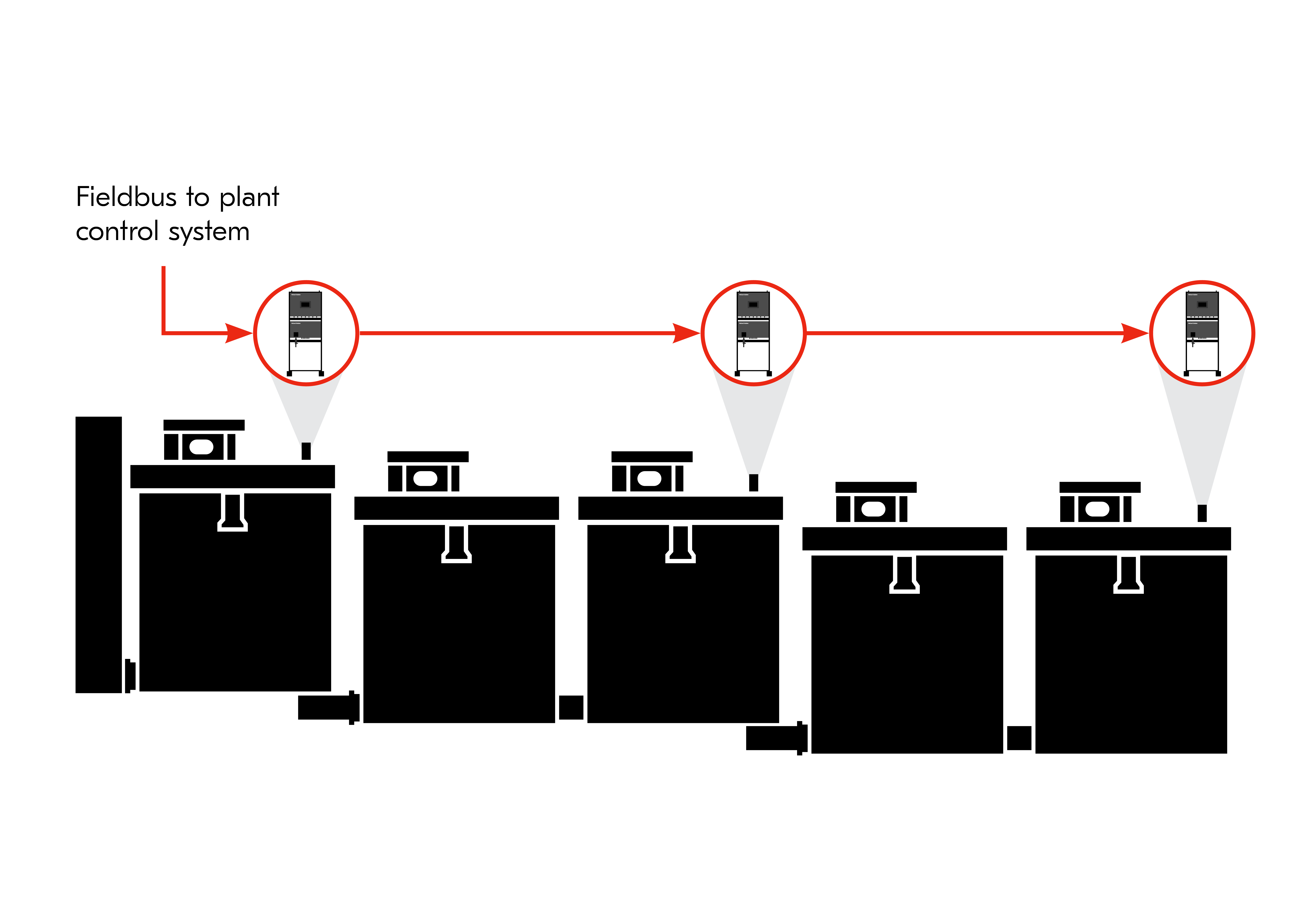

Controlling pulp levels in flotation cells is a complex task with many different aspects, such as the effect of cell structure and valve sizing, to take into account. Control becomes more challenging as the number and complexity of cells in a configuration increases.

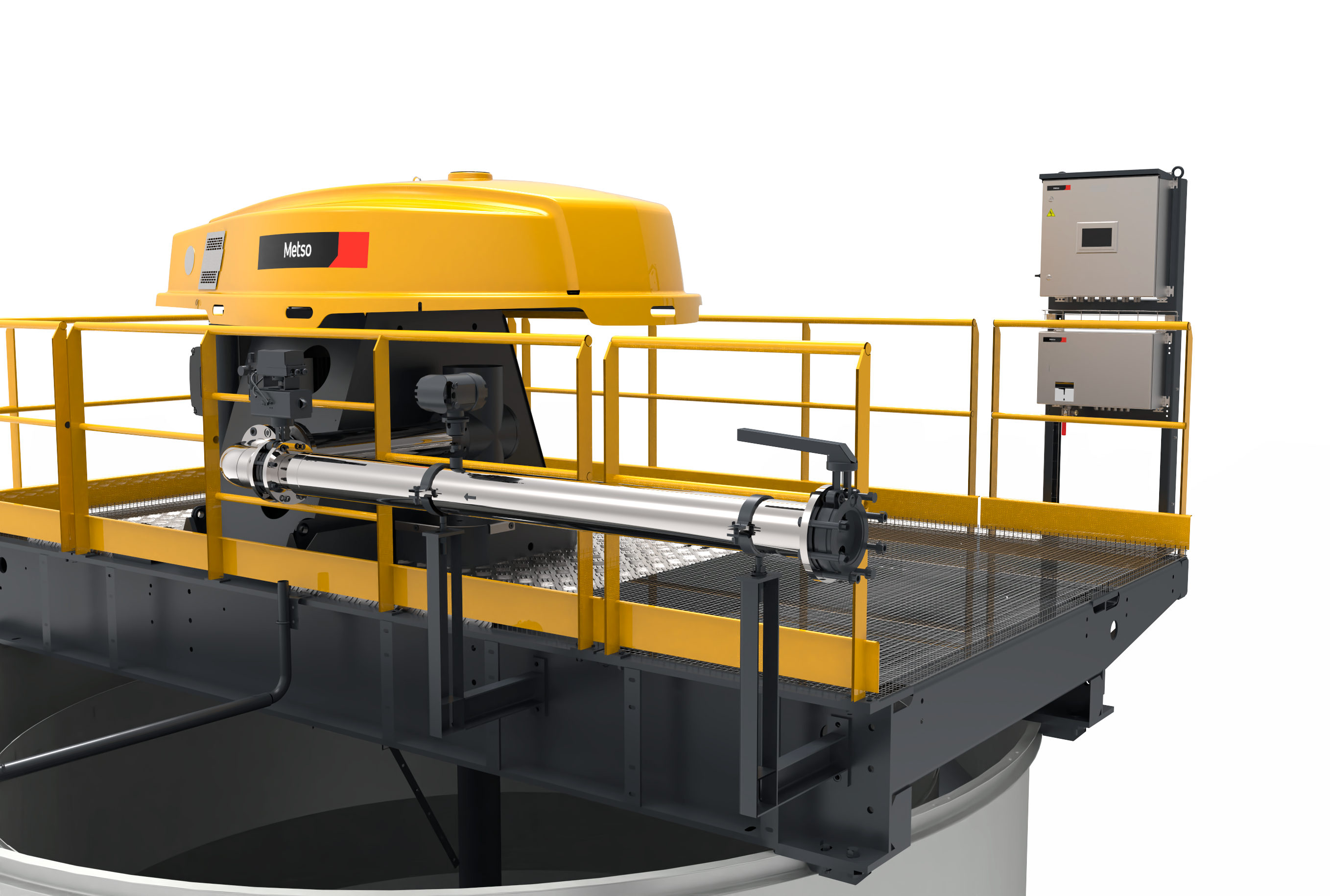

The second-generation Metso® CellStation builds on the success of the previous-generation solution and is based on Metso’s strong track record in this field, with more than 400 units sold since its introduction in 2008.

Maximized availability with comprehensive support

Because Metso CellStation uses hardware and software components that are common to many Metso product lines, support is readily available from our extensive team of experts to minimize downtime. This also helps to reduce the need for specialized training of on-site operators

Accurate level control and increased process stability

The pulp level is stabilized by the embedded Metso ExactLevel controller. Compared to traditional PID controllers, Metso ExactLevel enables more accurate level control and significantly reduces process disturbance, resulting in more stable froth conditions and therefore improvements in the flotation cell’s metallurgical performance.

Metso ExactLevel operates in conjunction with the standard PID control and compensates for disturbances generated by upstream sources before they affect the pulp level in the cell.

Metso CellStation has connectivity with the Metso FrothSense sensor system, which measures essential properties of froth appearance, including froth speed, direction, bubble size, froth stability, and froth color and provides statistical data related to these variables.

Typical scope

- PLC cabinet

- Instrument air manifold with

integrated filtering

- Cables and installation accessories

- Automation engineering, configuration,

and factory acceptance testing