Concorde Blast Tube™ upgrade

Improve the metallurgical performance of your existing self-aspirated pneumatic flotation cells

The need to process more finely disseminated and complex ore grades, as well as declining ore grades and the demand for improved flotation selectivity, all bring new challenges to minerals processing flowsheets.

The Concorde Cell technology helps flotation circuits overcome these challenges and achieve improved efficiency in fine and ultra-fine particle recovery.

Superior recovery | Innovative technology |

|---|---|

| • Superior recovery of fine and ultra-fine particles | • First fine and ultra-fine solution for previously inaccessible ore types |

| • Very high shear environment with increased bubble surface area flux for faster flotation kinetics | • Pre-aerated slurry raised to supersonic velocities and exposed to high local energy dissipation for increased bubble particle collection |

| • Optimized froth recovery and improved selectivity | • Blast Tubes treat 100% of fresh feed combined with tailings internal recycle for improved performance |

| • Forced air allows wider process control and stability for further flotation optimization | • Flotation cell froth area and froth washing designed for process duty requirement |

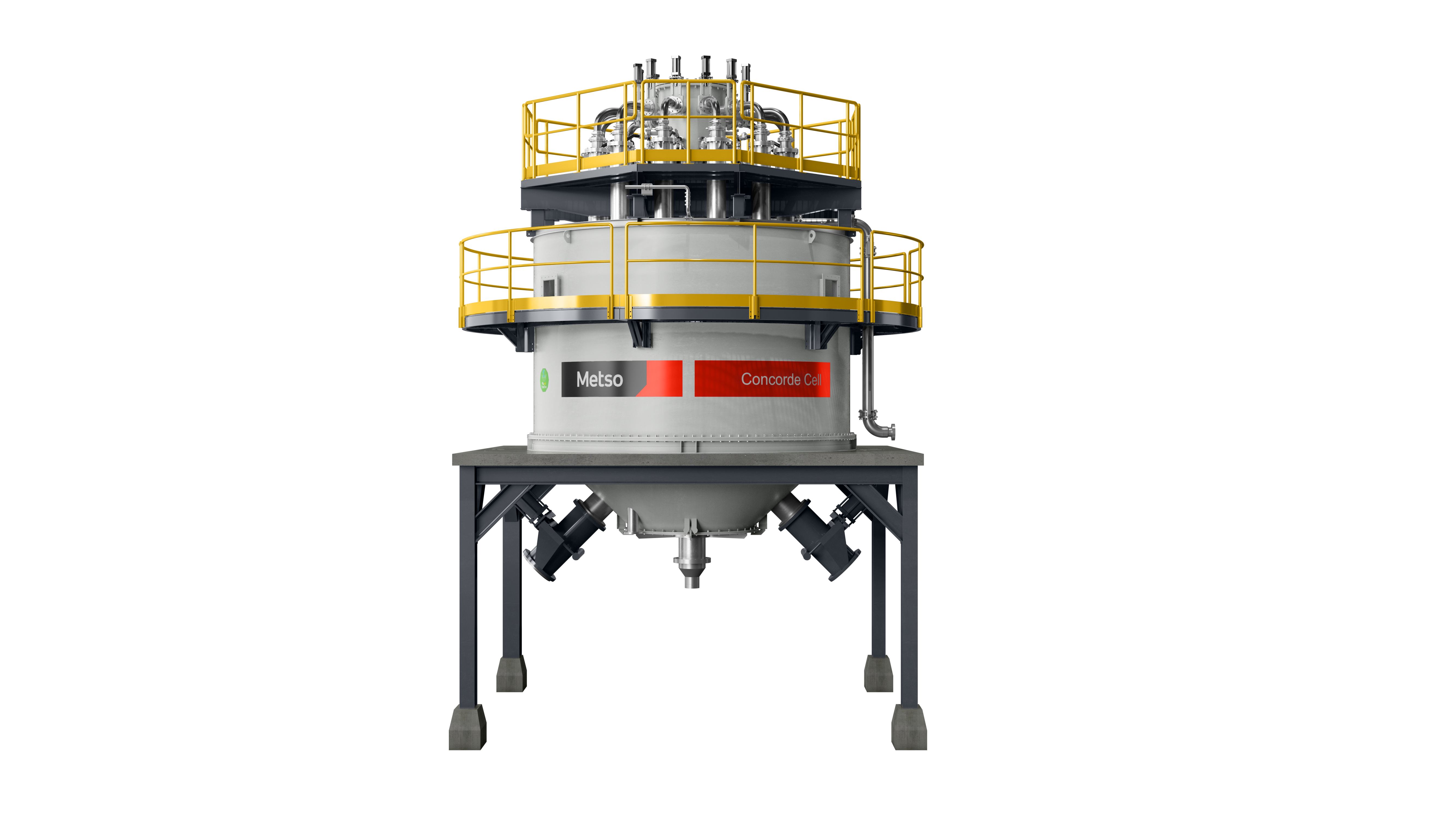

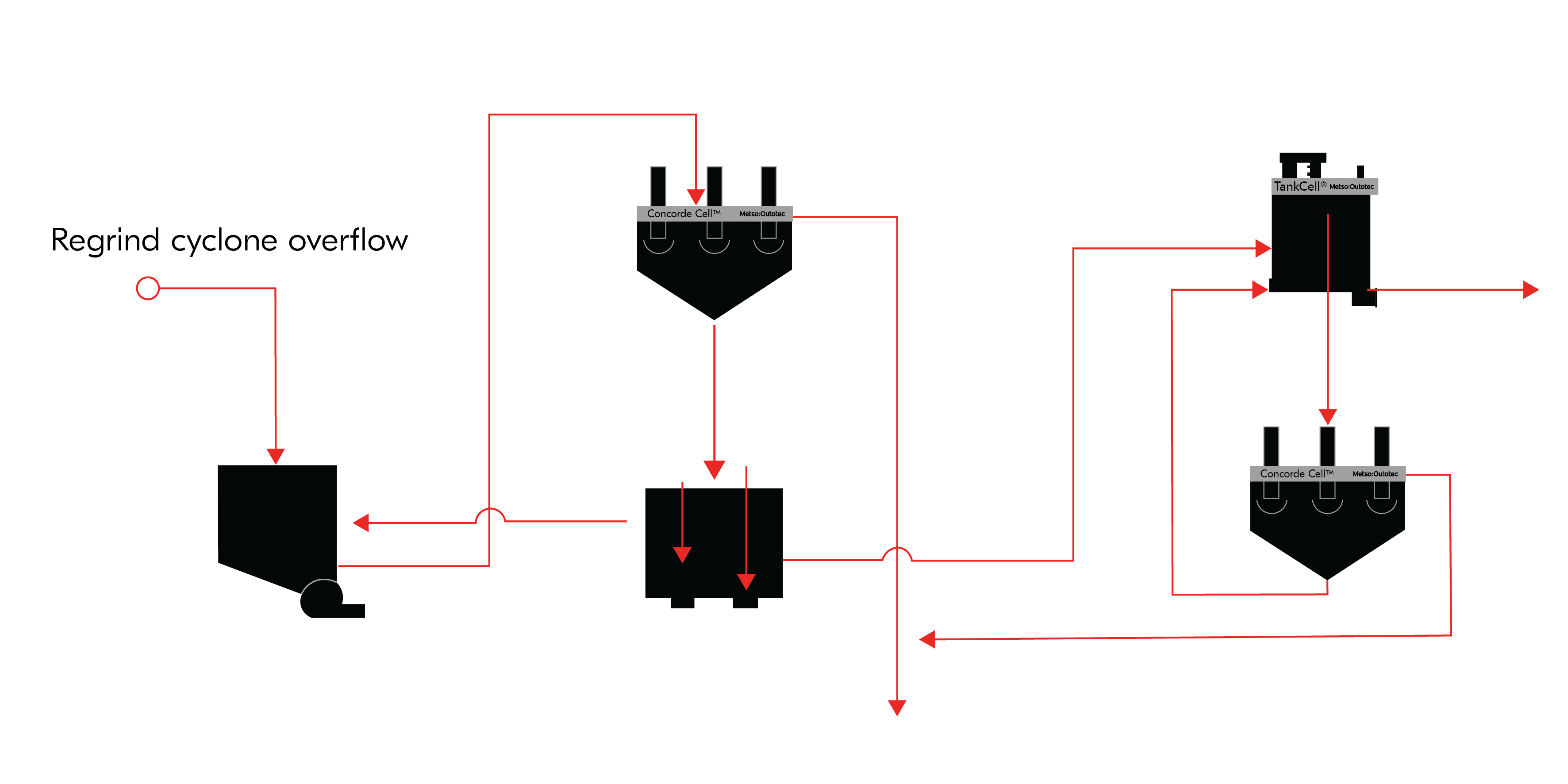

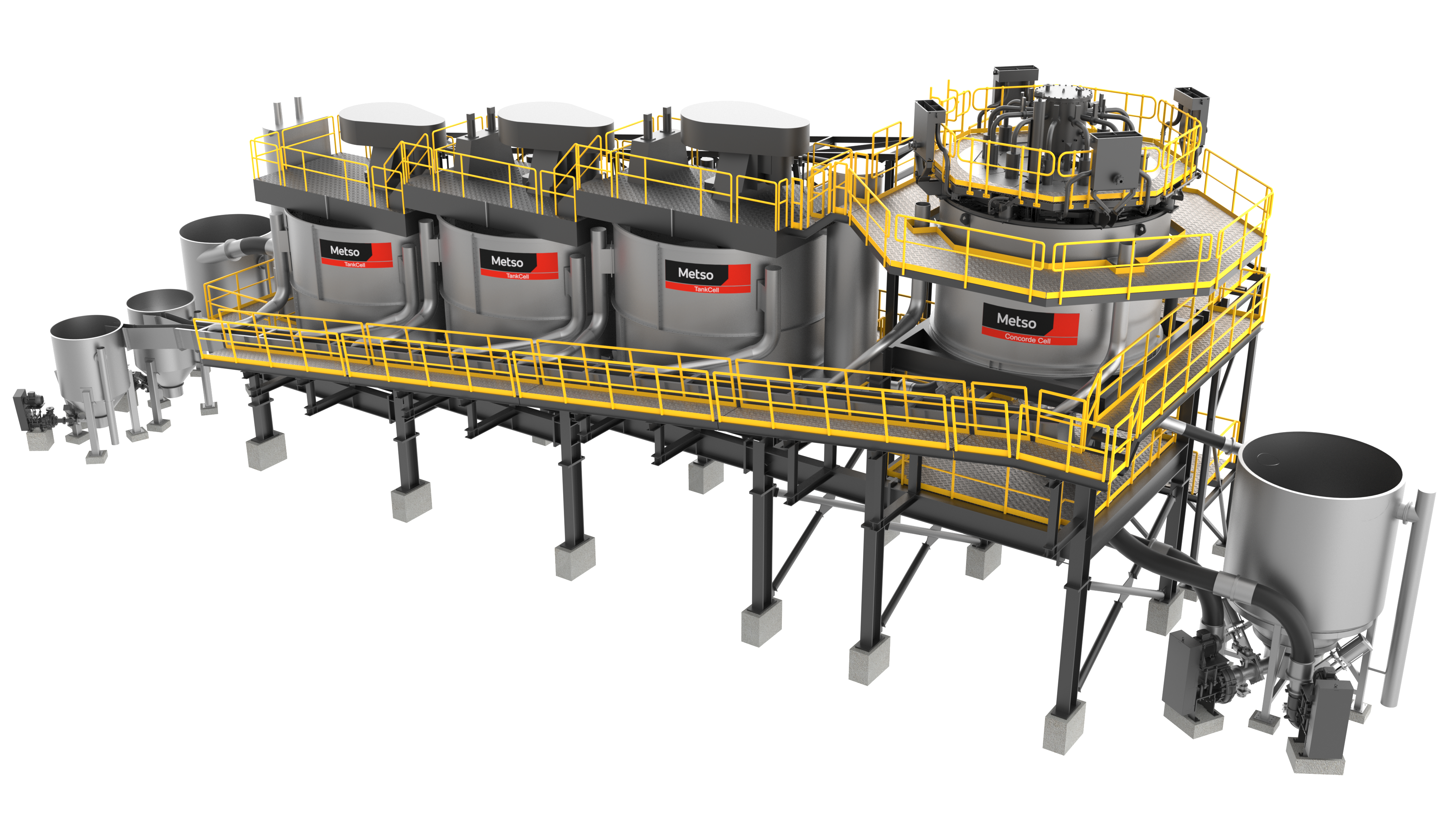

The Concorde Cell is Metso’s proposition for more finely disseminated and complex orebodies. Combining the well-proven TankCell® with Concorde Cells is a low risk and high benefit approach for minerals processing flowsheets.

The Concorde technology offers a superior recovery rate for fine and ultra-fine particles. The cell produces very high shear and extremely fine bubbles which increases recovery in particles under 20 microns.

Key features

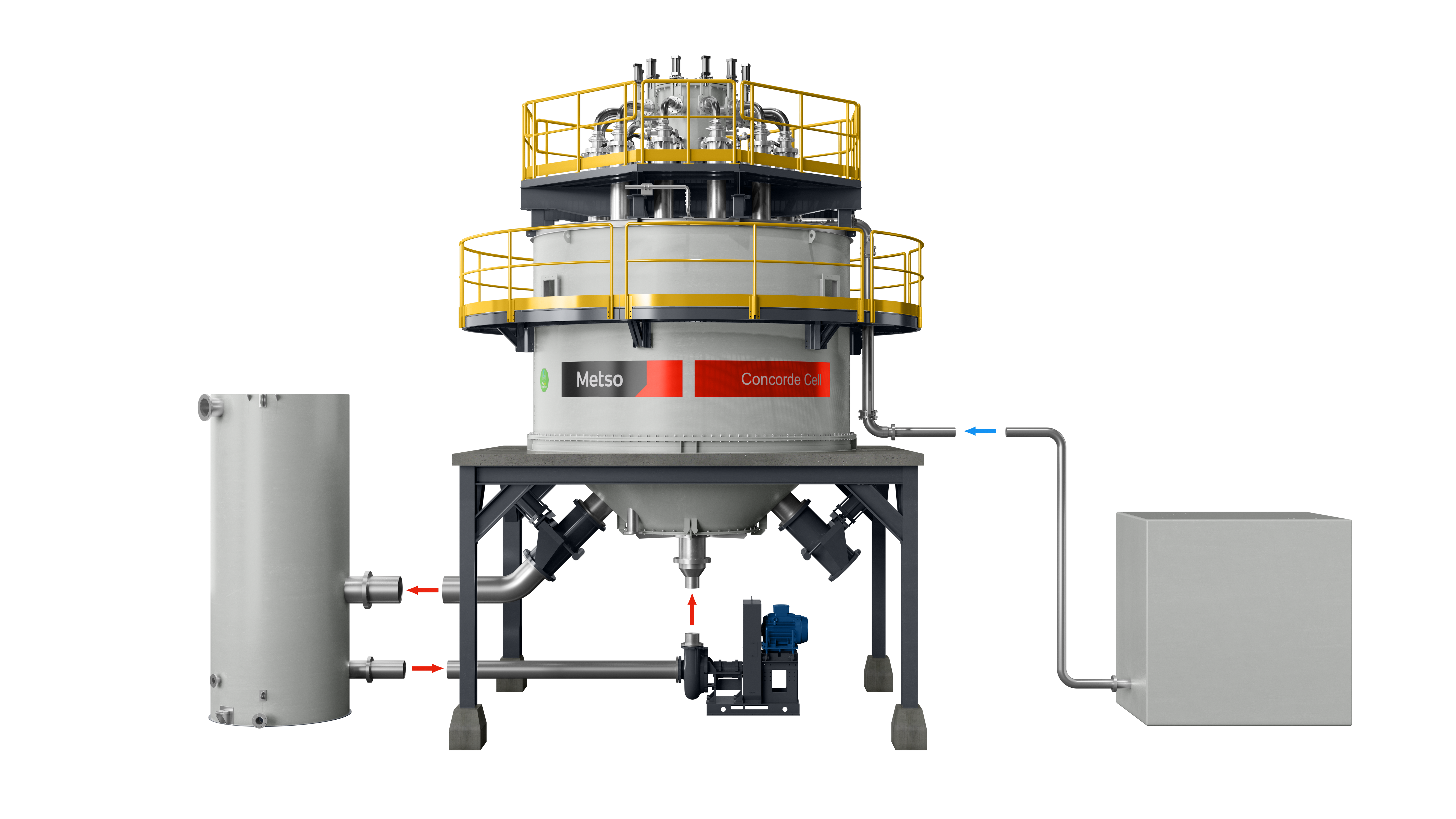

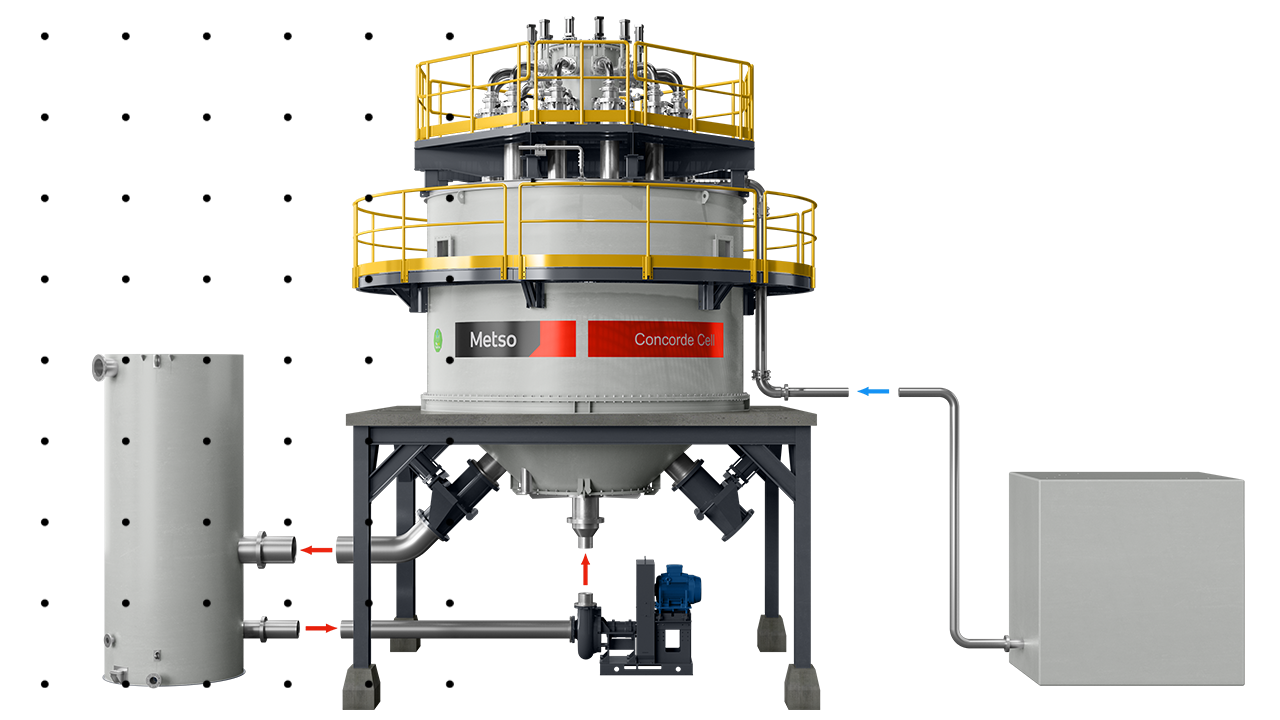

• High energy dissipation and smaller bubble size distribution produced by supersonic shockwaves

• Forced air allows higher air-to-pulp ratios

• Internal tailings recycling and integrated level control independent of flotation air control

The patented Concorde technology is the first fine and ultra-fine solution for complex and previously inaccessible ores types within various mineral processing flowsheets (e.g. gold, copper, nickel, platinum, silver, lead, zinc and molybdenium).

The Concorde forced air Blast Tubes treat 100% of fresh feed combined with tailings recycling for improved performance, so it allows for finer grinding to get extra liberation without the risk of valuable particles being reported into tailings.

Concorde Cell™ joins Metso Plus portfolio

The Concorde technology enables efficient use of earth´s resources with increased recovery of fines and smaller plant footprint, helping miners to minimize energy and water consumption per metal production targets.

The Concorde Cell is part of the Metso Plus portfolio, which focuses on the most environmentally efficient technologies (>100) in our portfolio.

The Concorde Cell Pilot Unit, a larger system, operates continuously for efficient, uninterrupted testing. It includes a recirculation system with an integrated PLC, allowing for the optimization of testing parameters. Metso offers on-site expert support as part of the package, along with a detailed testing report generated using Metso’s HSC software.

Key benefits

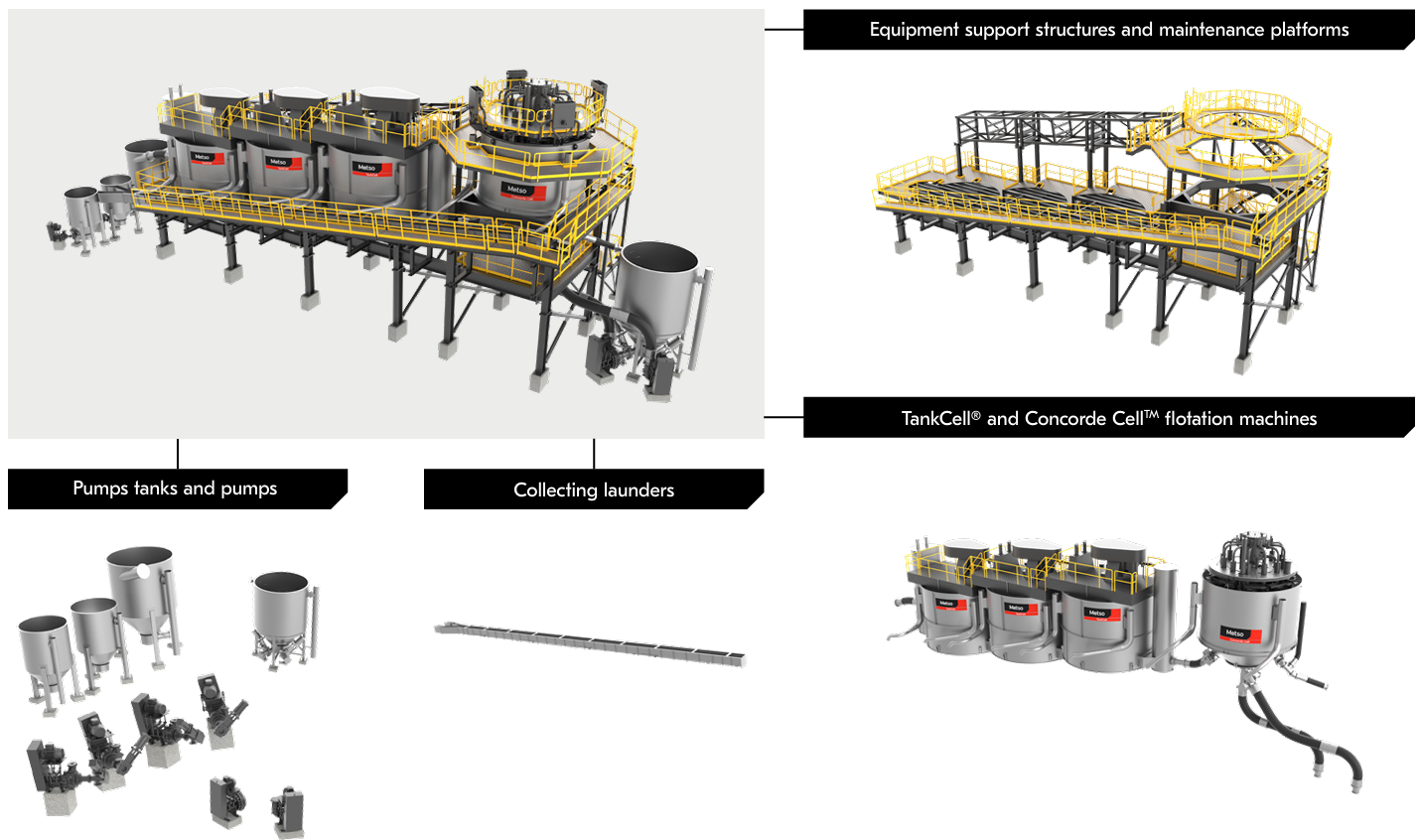

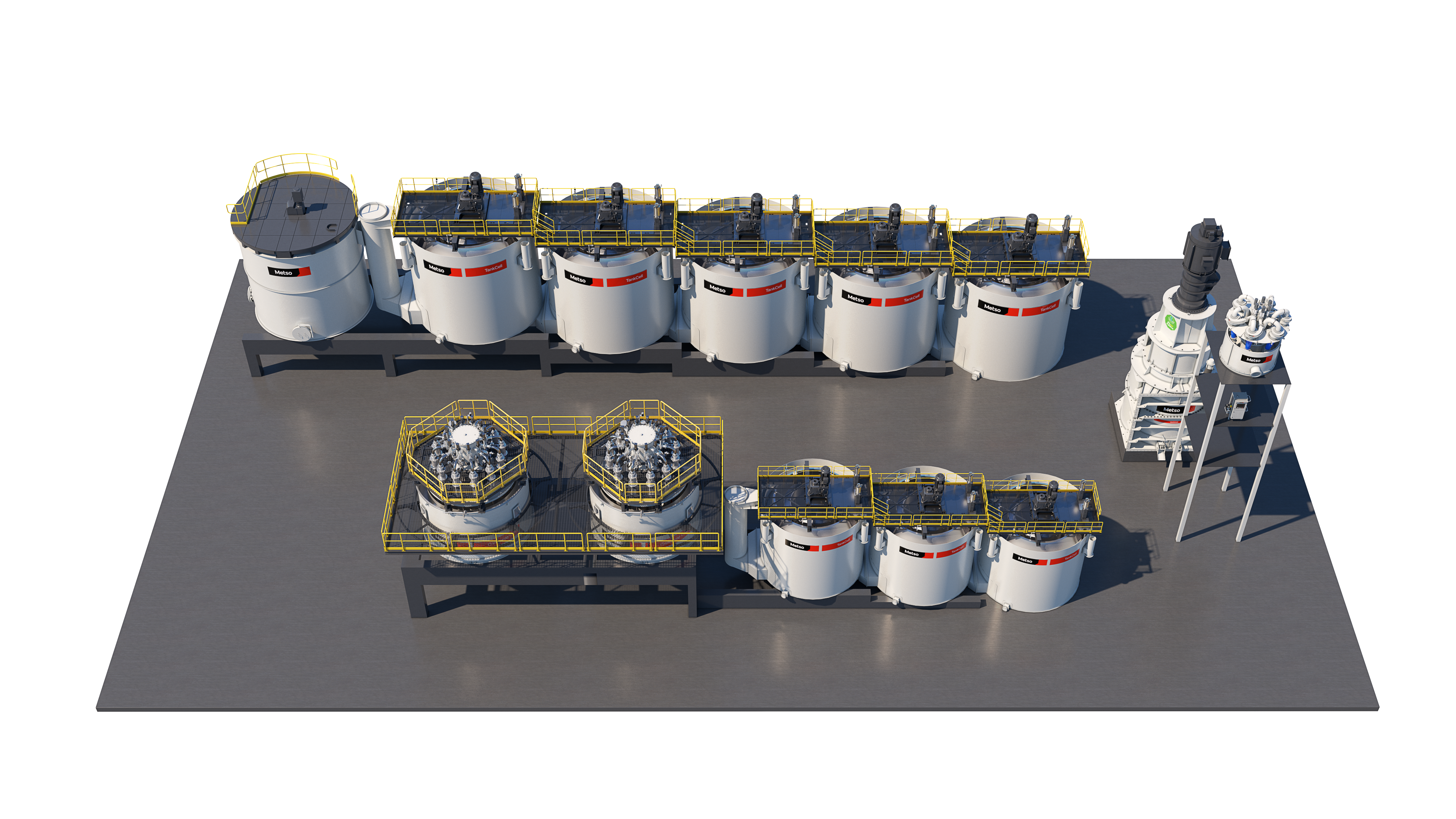

Effortless modular installation for accelerated results.

As a modular solution for safer installation and faster ROI in ore recovery, the Metso Concorde Cell™ Plant Units ensure superior quality implementation through maximized pre-fabrication in a controlled workshop environment with minimized on-site works.

Learn more about the Concorde Cell™ Plant Units.