Over 12,000 jaw crusher installations since 1975

Read the story behind Nordberg® C Series™ jaw crushers

Supporting your operations, from plant design expertise to equipment, parts and services for every stage of your process.

Are you looking to increase production, reduce risks, lower operating costs and enhance environmental performance? Then you are in the right place.

From the design and supply of products for a greenfield plant, to the addition of a single machine for an existing production line, we are here to help.

Rely on OEM experts because not all parts are created equal. Spare and wear parts built to perform.

Helping you get the most out of your equipment and processes.

Extremely reliable

Outstanding performance

Safe to operate and maintain

Easy to install and transport

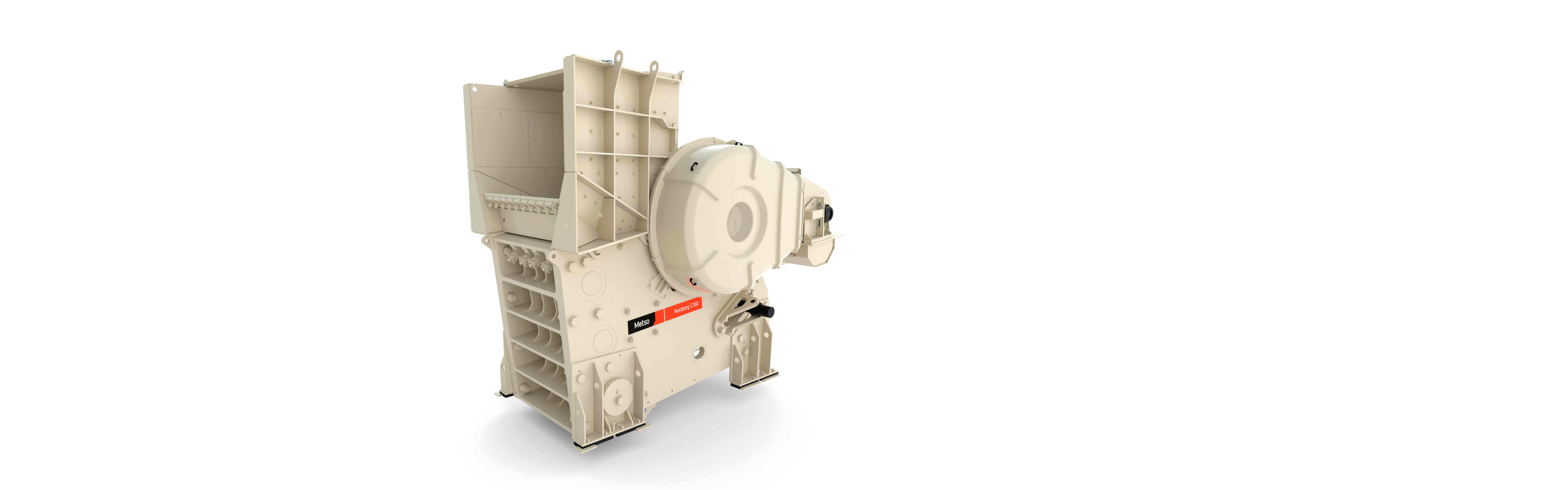

Nordberg® C160™ jaw crusher is designed to be extremely reliable. Its equipped to meet the expectations of customers who run their primary crushing plants 24 hours a day.

Based on customer experience and comprehensive testing, the critical areas of Nordberg® C160™ jaw crusher are protected against wear. The vital parts are also quickly and easily changeable if needed.

An extended feed opening accepts material over one meter (40”) and breaks it by the increased stroke at the top of the cavity. The tight nip angle in the middle of the cavity ensures that the processed material is quickly passed to the bottom of the cavity where the crusher’s long stroke finishes the job.

Like all Nordberg® C Series™ jaw crushers the Nordberg® C160™ jaw crusher is built out of premium components. The main frame structure is based on unique pinned and bolted connections without welded seams.

Nordberg® C160™ jaw crusher is engineered for safe operation and easy maintenance. There are limited number of service points, all with easy and safe access. The operation, condition monitoring and greasing can be fully automated. Lifting tools for components are supplied as standard to make maintenance simpler and safer.

The modular design enables wide range of bolt-on options like motor base, feed chute, and composite guards. Multiple installation alternatives from low profile to surface installation either on steel or concrete structure are possible. Nordberg® C160™ jaw crusher can be dismantled for transport and then reassembled, which makes it utilizable also at the underground sites.

| Power | 250 kW (350 hp) |

| Operating speed | 220 rpm |

| Weight (basic unit) | 76 300 kg (168 213 lbs) |

| Feed opening width | 1 600 mm (63”) |

| Feed opening depth | 1 200 mm (47”) |

| Minimum closed side setting | 150 mm (6”) |

| Maximum closed side setting | 300 mm (12”) |

| Capacity up to, scalped feed, maximum setting | 1 145 Mtph (1 260 Stph) |

| Capacity up to, non-scalped feed, maximum setting | 1 909 Mtph (2 133 Stph) |