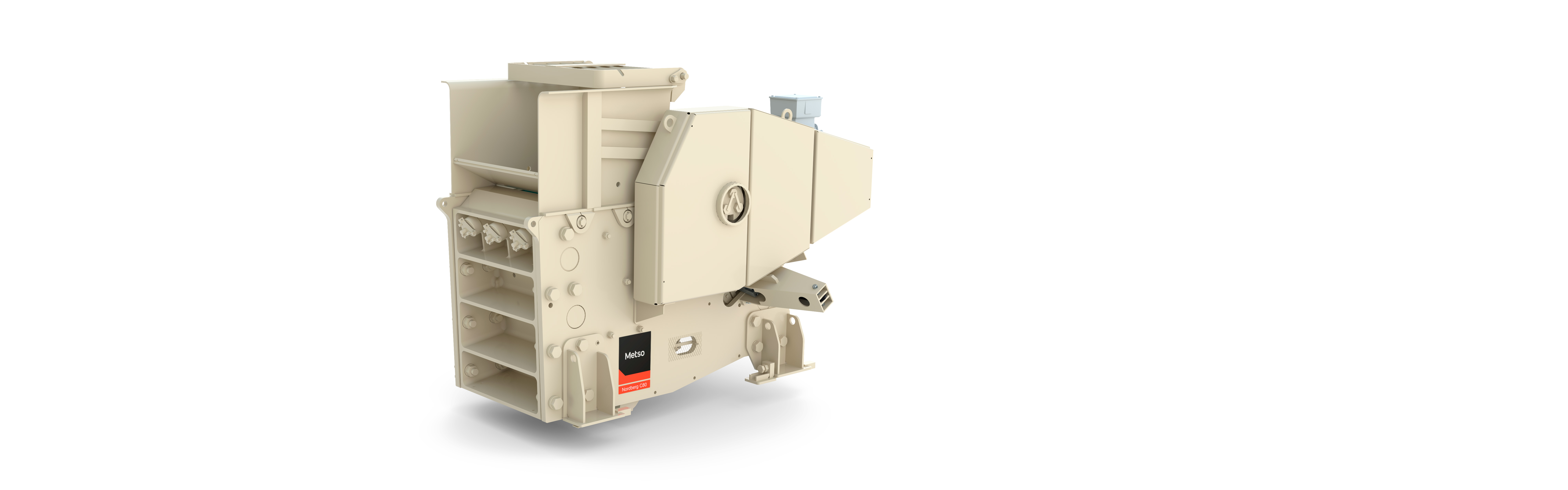

Over 12,000 jaw crusher installations since 1975

Read the story behind Nordberg® C Series™ jaw crushers

Supporting your operations, from plant design expertise to equipment, parts and services for every stage of your process.

Are you looking to increase production, reduce risks, lower operating costs and enhance environmental performance? Then you are in the right place.

From the design and supply of products for a greenfield plant, to the addition of a single machine for an existing production line, we are here to help.

Rely on OEM experts because not all parts are created equal. Spare and wear parts built to perform.

Helping you get the most out of your equipment and processes.

Extremely reliable

Outstanding performance

Safe to operate and maintain

Easy to install and transport

Even though Nordberg® C80™ jaw crusher is commonly used as a primary crusher, it also performs well in other roles, depending on the processed material and application.

Nordberg® C80™ jaw crusher is the smallest model in the popular Nordberg® C Series™ jaw crushers product family. It has a small nip angle and excellent kinematics that ensure aggressive crushing along the whole length of the crushing cavity.

Nordberg® C80™ jaw crusher is also equipped with an easy stroke adjustment, which makes it adaptable for different needs.

Safety and reliability have been important design principles of Nordberg® C80™ jaw crusher. The non-welded frame construction ensures excellent fatigue strength and extended crusher lifetime. The composite guards are lighter and durable making them faster and easier to handle. Special lifting tools that make maintenance safer for personnel are always in standard scope of delivery.

Nordberg® C80™ jaw crusher is easily installed in surface, underground or mobile applications. The pin and bolted structure enables that the jaw crusher can be swiftly disassembled and transported cost-effectively. Steel fabricated subframe for surface installations is available as option.

| Power | 75 kW (100 hp) |

| Operating speed | 350 rpm |

| Weight (basic unit) | 7 650 kg (16 870 lbs) |

| Feed opening width | 800 mm (32”) |

| Feed opening depth | 510 mm (20”) |

| Minimum closed side setting | 40 mm (1 5/8”) |

| Maximum closed side setting | 175 mm (7”) |

| Capacity up to, scalped feed, maximum setting | 335 Mtph (370 Stph) |

| Capacity up to, non-scalped feed, maximum setting | 514 Mtph (575 Stph) |