Selecting crushing chambers for cone crushers

Read what to take into consideration when selecting suitable wear liner for your application

Applying the strictest standards and tolerances for guaranteed safety and reliability.

Optimal chamber selection coupled with long-lasting wear parts support your production and sustainability targets.

Whether your crusher is two or twenty years old, get the exact parts and components for your operation.

We support you from over 150 locations globally from recommended parts lists to installation to upgrades and beyond.

Expert Series and Max Series cone crusher wears for extended wear life and optimized performance

Our premium crusher wear parts for cone crushers include the Metso Expert Series and Metso Max Series. We also have the expertise and tools to offer customized solutions and chamber optimization services to find the optimal crusher wear parts for your specific application, improving your crushing performance and cutting cost per ton.

With the help of our Chamber Selection Service, Chamber Expert Service and Chamber Optimization Service, we work with you to identify just the right level of solution to meet the demands of your application.

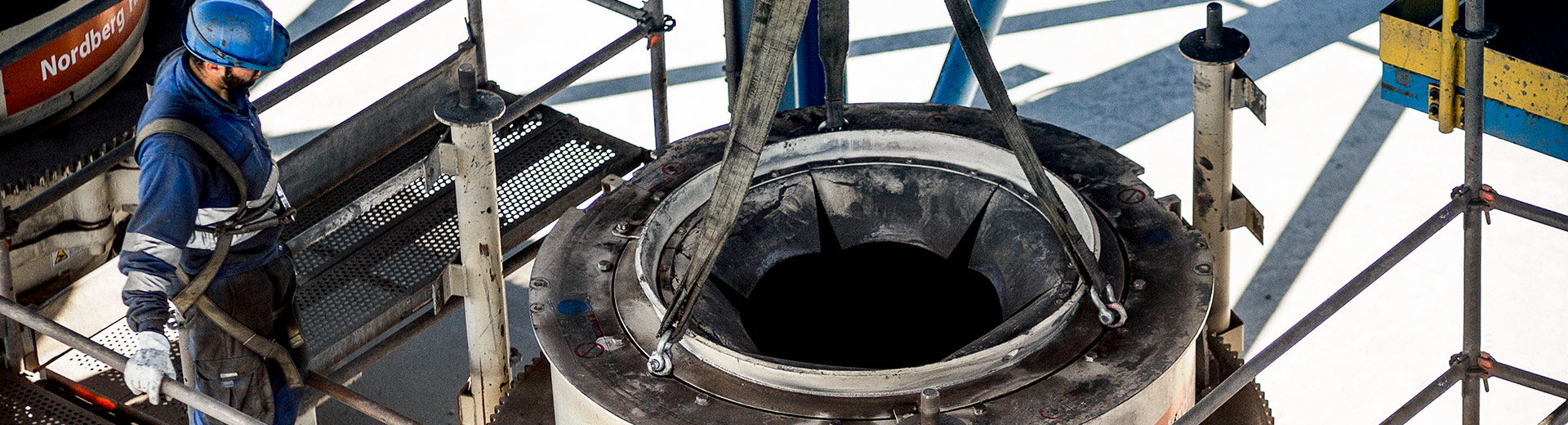

Our selection of cone crusher wear parts ensures that there is a solution for your application. We have the expertise to select both the chamber and the alloy to fit your crushing operation. The right wear profile improves crusher performance and extends wear life, leading to less downtime and fewer liner replacements, which in turn increases safety, reduces the cost per ton and the environmental impact. Our cone crusher wear parts are available for all Metso crushers, but we also offer crusher wears for third party crusher brands. We also offer lifting tools to make the cone crusher maintenance safer and more efficient.

Crusher wear part offering

With over 100 years of experience and our knowledge of crushers and different minerals processes, we know how crusher wear parts fit and function within a crusher to provide maximum performance. Our cone crusher parts are designed to the same specifications and standards as our cone crusher equipment, ensuring equipment compatibility for reliable, safe and sustainable operation.

Carefully produced at our own foundries

We have complete control over quality at every step of the process, from the selection of raw materials to final production. Metso cone crusher wear parts are made of high-quality manganese in a continuously monitored process at our own foundries and manufacturing facilities.

Get the maximum potential out of your size reduction process to achieve improved crushing performance and lower cost per ton. By using our unique simulation software, our chamber optimization experts can design an optimized crushing chamber that matches the exact conditions you are operating under.

Excellent value in standard crusher wear parts

Sometimes all you need is just the wear part. O-Series provides affordable standard parts from our stock – quickly and flexibly. With the right, reliable and safe wear parts by the trusted OEM, your working days are more productive and your operating costs lower.

Whether you are looking for just a quick replacement, planning to upgrade to a new safety or environmental standard, or in need to remove a production bottleneck, having the proper parts supply is critical. You can count on the engineering, production and supply of the OEM.

With multiple fabrication options and upgrades to choose from, Metso's cone crusher parts are eliminating the risk that the replaced or upgraded part becomes the weak point. They offer stable production without unexpected downtime.

Main components

Common components

All our spare parts are designed to the safety and environmental standards.

We also offer high-quality crusher spare and wear parts for crushers made by other manufacturers.

Contender™ Series crusher parts

Contender™ Series spare and wear parts are designed to fit and perform with Sandvik CH, CS and CJ crushers. The premium spare parts are designed using our OEM know-how. Selected spare parts are enhanced with better safety, easier maintenance and longer life. Wear parts are designed to meet OEM standards, going well together with Contender™ Series spare parts. Wear parts for CH430 and CH440 crushers are further complemented with lifting tools.