Introducing Nordberg® HPe Series™ cone crushers

The new Nordberg HPe range offers more performance and more uptime in a more sustainable way.

Optimized performance

Revolutionary combination of crusher speed, eccentricity, and cavity profile.

Cost efficient and ecological

Designed to save energy and reduce your investment cost.

Safe and user friendly

Engineered for your needs for improved safety and operation.

Less downtime, more confidence

Reliable and operating for longer.

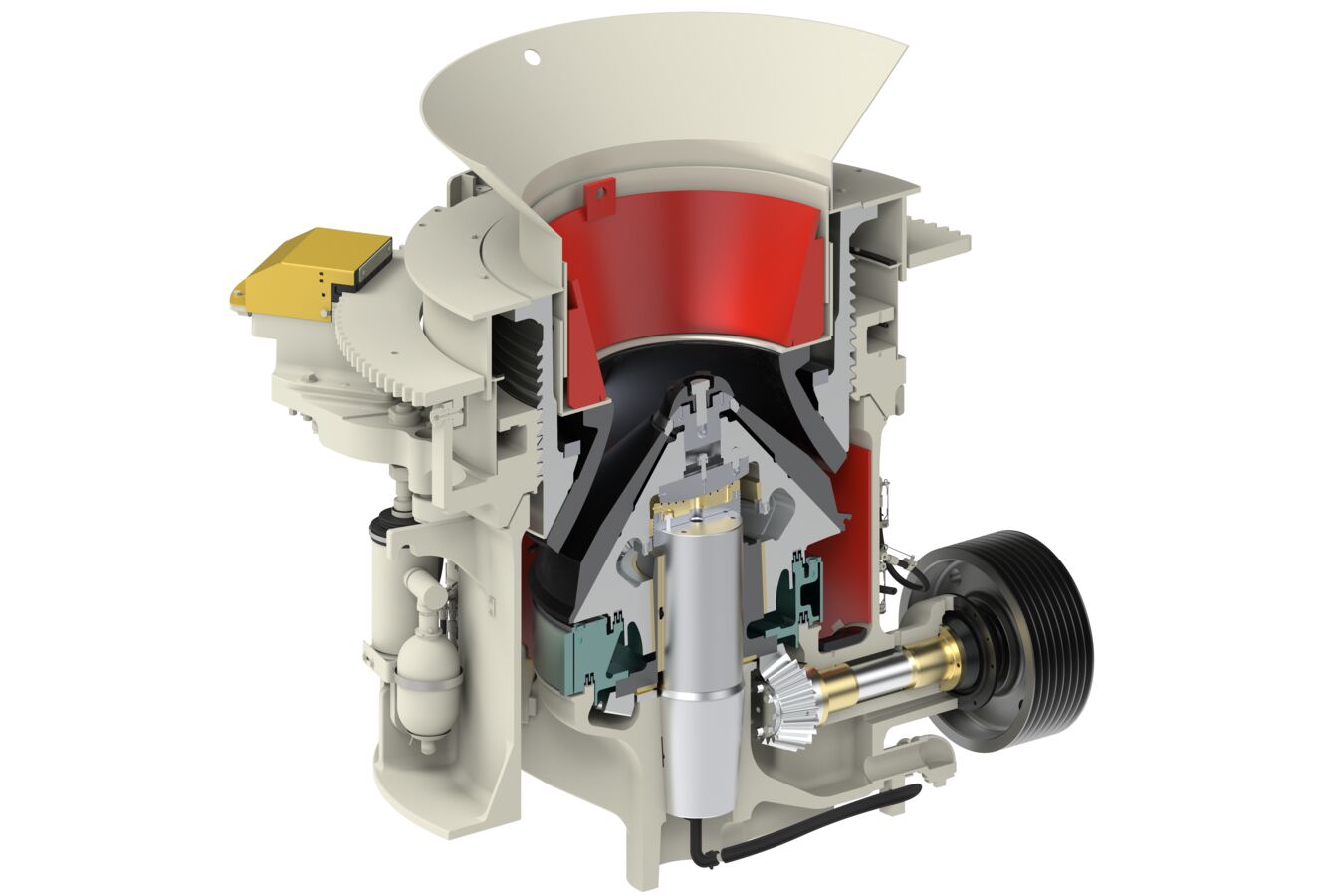

Nordberg® HP™ crushers features an unique combination of crusher speed, throw, crushing forces and cavity profile. These features help the HP Series provide higher capacity, better product quality and suitability to a wider range of applications.

From limestone to compact hematite, from ballast to manufactured sand production, and from small aggregate plants to large mining operations, Nordberg HP crushers are unbeatable in secondary, tertiary, and quaternary applications.

All Nordberg HP Series crushers are available as stationary, and many models as mobile or portable versions.

In a size-class comparison, Nordberg® HP™ crushers have a higher output capacity and reduction ratio. The higher density in the crushing chamber improves the inter-particle crushing action, resulting in superior product shape and increased on-spec end products with the same energy consumption. The crushers are equipped with the latest high-efficiency motors, making them efficient and ecological crushing machines.

Nordberg HP crushers produce finer products by limiting crushing stages, which lowers your investment cost and saves energy. This is achieved through a combination of optimized speed, large throw, crushing chamber design and increased crushing force. The efficient crushing action of the best power utilization per cone diameter.

Designed for your needs, Nordberg® HP™ crushers ensure maximum operator safety and user-friendly maintenance. Quickly access all of the main components from the top of the crusher. Simply press a button to remove the bowl with a mechanical rotation. Dual-acting hydraulic cylinders significantly reduce downtime and are more environmentally friendly. Maintenance tools are also available.

Another way Nordberg® HP™ crushers deliver is through less downtime and increased operator confidence.

Dual-acting hydraulic tramp-release cylinders are used to let the crusher pass tramp iron and to provide a large clearing stroke if needed.

The accumulators arrangement provides better reactivity of the hydraulic system.

Metso crusher automation systems further improve the operation of your Nordberg® HP™ crusher. And can increase your production by more than 10%.

With Metso crusher automation you can control maintenance, setting modifications, production follow-up and data extraction. All parameters can be adapted to your plant characteristics, and you can easily do all this close to the crusher or remotely from the control room.

You set the goals and reach them. It allows you to monitor the feeding, change the settings automatically depending on the load or liners wear, and select the product size distribution according to your preference of coarse or fine production. (or fine aggregate and mining production.)

MODEL | HEAD DIAMETER | POWER | WEIGHT* | FEED OPENING | CAPACITY UP TO |

|---|---|---|---|---|---|

| Nordberg® HP100™ | 735 mm (29") | 90 kW (125 hp) | 6 470 kg (14 300 lbs) | 150 mm (5 7/8") | 155 Mtph (170 Stph) |

| Nordberg® HP200e™ | 940 mm (37") | 160 kW (200 hp) | 12 300 kg (27 000 lbs) | 220 mm (8 3/4") | 290 Mtph (320 Stph) |

| Nordberg® HP3™ | 1 000 mm (39") | 250 kW (350 hp) | 16 100 kg (35 600 lbs) | 220 mm (8 3/4") | 388 Mtph (427 Stph) |

| Nordberg® HP350e™ | 1 120 mm (44") | 250 kW (350 HP) | 18 300 kg (35 200 lbs) | 250 mm (9 7/8") | 485 mtph (535 Stph) |

| Nordberg® HP4™ | 1 120 mm (44") | 315 kW (400 hp) | 24 200 kg (53 400 lbs) | 252 mm (9 7/8") | 555 Mtph (610 Stph) |

| Nordberg® HP400™ | 1 320 mm (52") | 315 kW (400 hp) | 25 600 kg (56 400 lbs) | 304 mm (12") | 630 Mtph (700 Stph) |

| Nordberg® HP450e™ | 1 320 mm (52") | 355 kW (450 hp) | 26 000 kg (57 000 lbs) | 345 mm (13.58") | 695 Mtph (765 Stph) |

| Nordberg® HP5™ | 1 250 mm (49") | 370 kW (500 hp) | 29 000 kg (64 000 lbs) | 317 mm (12 1/2") | 600 Mtph (661 Stph) |

| Nordberg® HP500™ | 1 520 mm (60") | 355 kW (500 hp) | 37 000 kg (81 600 lbs) | 351 mm (13 4/5") | 790 Mtph (870 Stph) |

| Nordberg® HP6™ | 1 400 mm (55") | 500 kW (650 hp) | 44 550 kg (98 200 lbs) | 331 mm (13") | 790 Mtph (870 Stph) |

| Nordberg® HP600e™ | 1 520 mm (60”) | 450 kW (600 hp) | 37 400 kg (82,500 lbs) | 369 mm (14.52") | 950 Mtph (1050 Stph) |

| Nordberg® HP800e™ | 1 650 mm (65") | 600 kW (800 hp) | 65 500 kg (144 400 lbs) | 356 mm (14") | 1720 Mtph (1895 Stph) |

| Nordberg® HP900e™ | 1 780 mm (70") | 700 kW (900 hp) | 77 960 kg (171 870 lbs) | 356 mm (14") | 2 000 Mtph (2 204 Stph) |

| * Complete crusher weight |

Get the maximum potential out of your size reduction process to achieve improved crushing performance and lower cost per ton. By using our unique simulation software, our Chamber Optimization experts can design an optimized crushing chamber that matches the exact conditions under which you operate.